What is disclosed in US8,485,245?

In the “pre” installment of this thread I briefly thought about Mashable's coverage of US8,485,245 (the ‘245 patent) that issued on July 16th. Here, I wish to consider three others.

In their coverage, gizmodo makes a few wonky statements, including “…it’s easier to make (no quick cooling required)…”. In reality any formation process for a BMG requires a very high cooling rate to avoid crystallization i.e. the unwanted structure. It is though the statement “And the patent is very clear about the fact that they’ll be turning the stuff into iPhones, iPads, watches, and “any electronic device known in the art.” This statement is no doubt derived from the paragraph between col.13, ln. 56 and col. 14, ln. 11 of the Detailed Description. Such a paragraph simply presents exemplary uses including current or potential, future devices. There are many more devices listed, including those that are unlikely to ever be part of Apple’s product line. In the end I do not find these sort of paragraphs all that interesting.

Forbes is another big name publication that took note of the ‘245 patent. It rolled a few thoughts related to the ‘245 patent into a larger discussion of Apple’s rumored iWatch. These thoughts appear in the 7th and 8th paragraph. It is mentioned that the ‘245 patent suggests Apple has worked out some limitations, and that Apple will need “defensible patents” because it is coming to the smart watch market late. I would suggest that this is too product centric, as the ‘245 patent presents a process for fabricating 2D sheets of Bulk Metallic glass (BMG). Now, if another smart watch were to use BMG in their casing one might consider asserting the ‘245 patent. This though is not for me to comment on further as there would be many more technical and legal considerations. In passing it is also worth noting that the title of the Forbes article reads, in part, “ … Curved Casing Could be Liquidmetal”. Again the ‘245 patent considers a process for 2D sheets, which may be subsequently processed into a curved casing, but one can not directly obtain curved structures from the processes of the ‘245 patent.

Electronista is credited as the first coverage of the ‘245 patent. While they also seem focused on the examples of possible electronic devices, and there are a few wonky statements here and there, they were the only ones to identify the process as “broadly similar to the float glass process used for making window panes.”

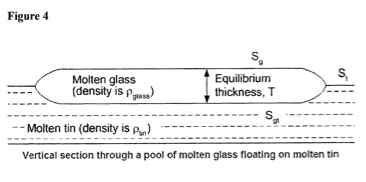

What can I add to this discussion? First, the process is indeed similar to that used to make sheets of silica-based glass i.e. window panes. It is worth noting that the phrase “float glass” is used throughout the ‘245 patent. I was first introduced to the process for silica-glass in my undergraduate days. It was always described as a big advance in the formation of window panes. It is interesting to see such an old process inspire the current work.

Second, the disclosure of the process really picks up steam at Col. 14, ln. 11 of the Detailed Description. For those interested in the process it is an interesting read. Generally, liquid BMG is poured from a hopper onto a pool of liquid metal such as tin. Of importance is this latter metal have a density that is higher than the BMG such that the BMG floats thereon. In such a system the liquid BMG will float over the surface forming a flat 2D sheet. Finally, the metal on which the BMG floats provides a good medium for the rapid heat conduction required to meet the necessary cooling rate. Figure 4 of the ‘245 patent is presented below for illustrative purposes. There are of course a number of embodiments and alternatives disclosed but that is the basic process.

One subsequent processing option is presented at col. 18, ln. 5. Very selective crystallization of the BMG is described wherein the crystallized structure is used to facilitate cutting. This particular idea may well be a kernel of further patentable subject matter related to post processing. I would anticipate more will come from work on the processing of the 2D sheets into structures for the end devices.

At the end of the day the methods disclosed in the ’245 patent approach a known issue in BMG processing, the formation of large dimensions. It is also apparent though that a phone, for example, can not be formed directly from a flat sheet. However, a flat sheet could well be a building block in the formation of a final structure.

The ‘245 patent discloses some interesting stuff. Stuff that may become a component in the “toolkit” for fabrication of BMG alloys. However, despite the feelings of many publications it does not extrapolate to a particular product. As a side note, it is interesting that the ‘245 patent was not been previously published. Its issue date is within 18 months of its filing date. That is pretty quick for the USPTO these days.