to wet or not to wet – GE’s metal wettability work

On October 15th MIT’s Technology Review published an interesting

article entitled “Water-Repelling Metals”. The article introduces GE developments around an anti-fouling metal surface and highlights a whole host of applications that might benefit. It is noted here that these are not niche applications. Rather they represent a spectrum of industrial applications that could be made more efficient or allow the elimination of related processes. Aircraft de-icing being one example of an environmentally nasty related process that might someday be mitigated through alteration of aircraft surface properties.

While indicating that GE was shy on technical details around these advances, the article noted that inspiration for the developments came from lotus-plant leaves that have a nanocrystalline wax structure. So what is GE doing?

Searching of the USPTO’s pre-grant patent database found several published applications of interest. Of these US20070031639 will be considered here. As suggested by the lotus-plant reference GE is developing textured surfaces which modify the wettability of the surface. US20070031639 describes surfaces that incorporate various geometries of features where the presence of the features, of a particular geometry, change the wettability of the surface.

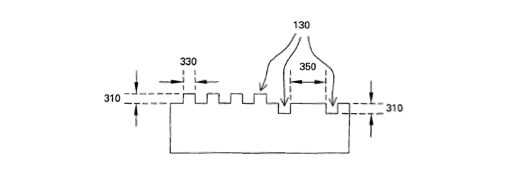

Aspects of the prescribed feature geometry can be discussed with reference to Fig. 3, reproduced below. The features 130 have a height 310 (h), a width 330 (a) and a spacing (b) that is not numbered. It is noted that the features 130 can be “above” or “below” the surface. Paragraph [0016] presents a broad range of feature shapes, including cubes, rectangular prisms, cones and nanowires.

With regard to material systems paragraph [0010] outlines that the surface may be a metal or a metallic alloy, while paragraph [0032] indicates that the features 130 may be a metal, intermetallic, semi-metal or non-metal, with the latter group including oxides.

Finally, paragraphs [0034] to [0037] present various possible methods of fabricating surface features 130. Anodized aluminum is presented as an example of a porous surface that might be appropriate.

Overall, this is probably an area of interesting future developments, particularly with regard to methods of fabricating the appropriate features in a given material system.