sierra energy and a blast furnace rethink

I always like encountering technology that either re-purposes or gains inspiration from an existing technology. There is a nice dose of lateral thinking.

I am however particularly interested when the story has a metallurgical twist, as was the case with Ambri and their liquid metal battery.

Now there is Sierra Energy, with their blast furnace inspired gasification system. The NYTimes recently took a look at the Sierra Energy story. They touched on many aspects, including some history around early insights and development, and more current work with the US Department of Defence. The article is well worth a read. That said I think there is room to flesh out aspects around Sierra’s technology a bit more. It is time to think about gasification.

There have been many incarnations of the gasification process, with variations on the input, the reaction process and the product. There are in fact too many combinations to summarize here. One can however ask three questions of any system to begin thinking about its viability. First, is there a net gain in terms of energy and/or end product during the process? Second, are there harmful emissions exiting the system? Third, is the process sustainable for a potentially widely variable input? If a technology can get over these three hurdles it will certainly be doing better than most systems that have come along to date.

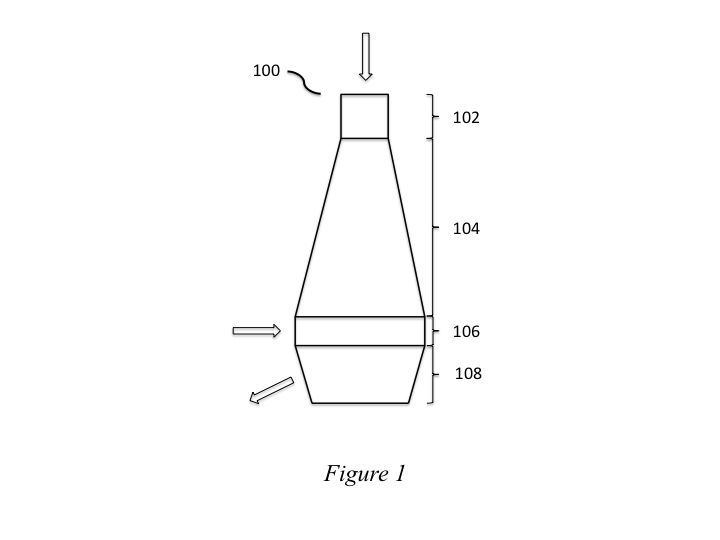

As mentioned at the outset Sierra Energy has turned to a blast furnace for inspiration. I would hazard that the basic design and operation of a blast furnace is suited to its application for the gasification waste. What is a blast furnace? Historically a blast furnace is a reaction vessel for the production of iron from iron ore. A schematic diagram of a basic, generic blast furnace 100 is presented in Figure 1. The solid reactants or charge enter(s) the furnace at or near its top in region 102. Straight away it is worth noting that a blast furnace 100 is essentially always full, and the process is continuous, with the charge slowly descending through the furnace. In region 104 the furnace widens towards section 106. It is in region 106 that air is traditionally blown into the furnace through ports called tuyeres. This air oxidizes a component of the charge, providing heat to the furnace. As such the temperature of the furnace is highest here. In an iron making process it will be above 2000oC. The temperature of the furnace and charge then decreases as one moves away from region 106 towards region 102. Finally, the liquid “product” is removed from region 108, which acts as a holding zone therefor.

The NYTimes article referred to a patent issued to Claflin and Jasbinsek. A brief search of the USPTO found US 6,030,430, which appears to fit the bill. While no recent patent applications assigned to Sierra Energy were found at the USPTO, one can envision further patents that build on the material disclosed in the ‘430 patent. This might include developments in the process conditions, including inputs to the furnace, process control, and any post processing. Further consideration of the system and process disclosed in ‘430 patent, thoughts on how this system might apply to the processing of waste and its evolution into the system depicted today are though for another forum.

OK … I am already over my word count so I should wrap up this post. At the outset I hazarded that the blast furnace may be suited to the processing of waste. In particular it may be suited to overcome the vexing problem of input variability. Yes, there was a comment to this effect in the NYTimes article, but it strikes me that a blast furnace is a system that can “integrate” or average an input stream. Remember, the furnace is always full and the charge moves continuously through the furnace, and its reaction zones. In this case the charge may appear, more homogeneous as compared to systems where the charge may travel through a reaction zone in a more instantaneous or “single pass” manner. In the end, the operational data will tell the story.